New Paragraph

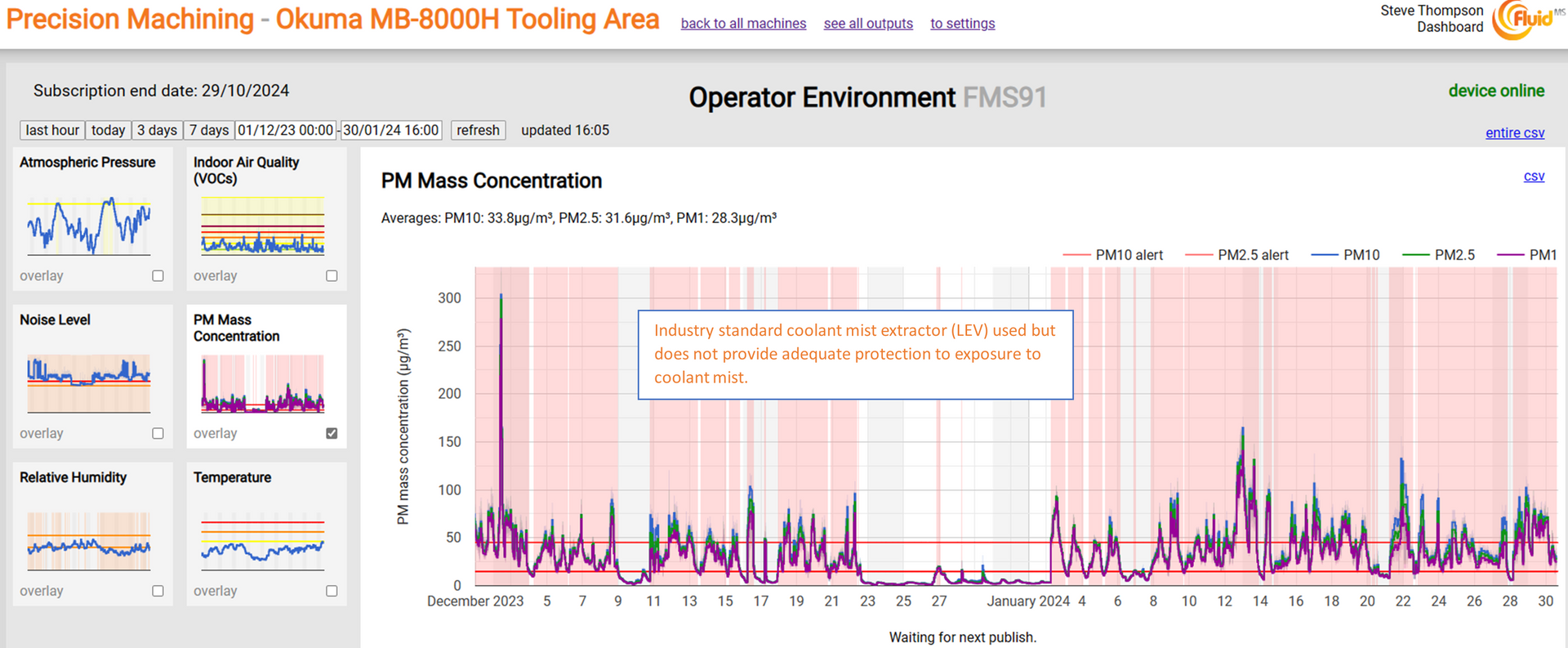

HEXmon users become proactive in identifying emission sources and quickly grasp the effects of mitigation efforts. With 'time series insight', informed decisions can be made and swiftly evaluated to determine the effectiveness of actions taken to reduce emissions

HEXmon SENSOR is designed for easy installation and user-friendly operation

It serves as a comprehensive platform for monitoring, alerting, and reporting.

Helping track daily variations in FACTORY INDOOR AIR QUALITY caused by emissions escaping from manufacturing processes.

HEXmon was developed with application experience, and is supported with SCIENTIFIC KNOWLEDGE to help understand risks and help implement change

- Dust, Fume & Mist contamination

- Total Volatile Organic Compounds

- Noise Levels

- Temperature, Relative Humidity & Atmospheric Pressure

Easy to use, secure, Dashboard Reporting

HEXmon empowers Health, Safety, Maintenance and Facilities Teams to effectively monitor the impact of emissions on air quality, enabling prompt action to mitigate risks.

- automated monitoring, alerting and reporting of air quality provides a more responsive solution compared to visually reading airflow indicators or pressure gauges.

- even if airflow indicators show acceptable levels, restricted flow can still lead to reduced air quality.

HEXmon supports traditional Occupational Health Exposure monitoring practises by providing a better understanding of day to day factory indoor air quality, insight into control measure performance and the impact of process changes

Click on the icons below to learn more of the capability of HEXmon

HEXmon solves the problem of NOT KNOWING