the deterioration of FACTORY INDOOR AIR QUALITY due to emissions (dust, fumes, mist etc.) escaping from manufacturing processes can result in significant health and environmental hazards

installing containment and control measures e.g. LEV extraction, demonstrates good practice, but doesn't necessarily PROVE a healthy working environment and creates a false sense of security

by continuously monitoring relative changes in emissions that impact air quality, we can better understand the

EFFECTIVENESS OF CONTAINMENT & CONTROL MEASURES,

refine risk assessments and progress towards achieving ALARP (As Low As Reasonably Practicable)

the Health & Safety Executive state

“people develop these diseases because they breathe…in airborne contaminants at work, often because control measures do not work well enough” Controlling airborne contaminants at work: A guide to local exhaust ventilation (LEV) HSG258

“....control measure may not always be reliable, despite checking and maintenance." revised guidance from the HSE on exposure to Respirable Crystalline Silica (RCS), issued March 2025

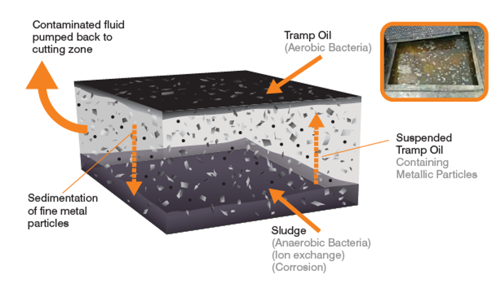

Application Insight - what contamination can be in metalworking fluids

Typically, MWF's become hazardous as soon as they are put into use.

In addition to the various chemicals used in their formulation, they may contain

- bacteria, fungi, endotoxins

(dip slide tests only provide a low percentage indication of live bacteria and not a total viable count)

- tramp oil

- particles of the material being cut

When MWF's are disposed of they are given a 6 digit European Waste Catalogue code followed by * which designates the waste as "ABSOLUTE HAZARDOUS"

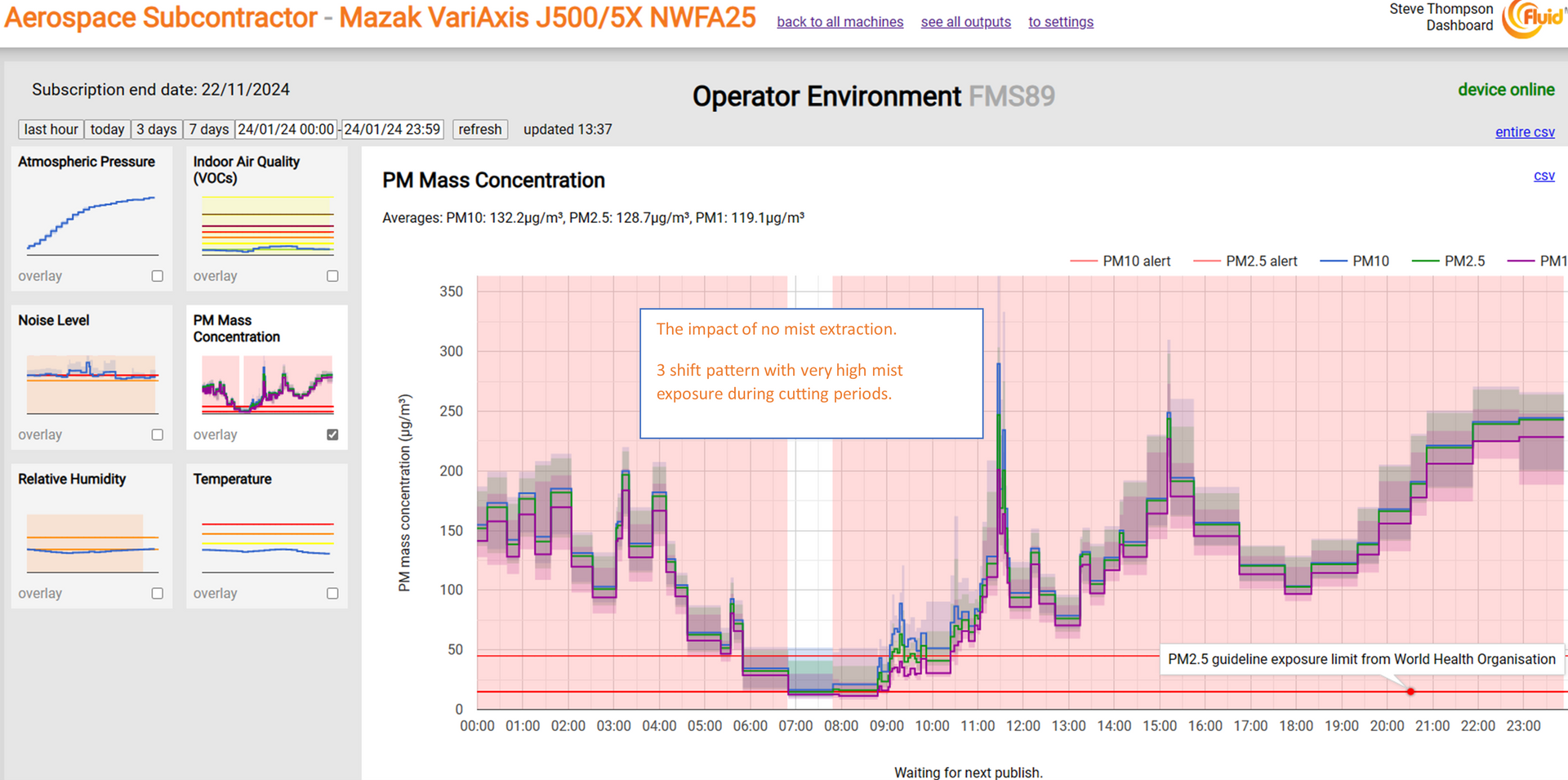

Containment & Control - how effective are recirculating type mist extractors

CNC platform do not provide 100% containment; emissions can leak from seals, conveyor tanks and filtration systems.

While high spindle speeds create more mist, particulate dispersion can also occur at slow spindle speeds.

Installing a 'fit for purpose' Local Exhaust Ventilation system is a positive step to reduce emissions at source.

But without continual air quality monitoring there is no way of knowing the effectiveness of the LEV.

As a primary control measure, installing a suitably specified LEV system helps reduce exposure to larger, ‘irritating’ particles ~>10µm

but does not eliminate the risk from exposure to harmful <2.5µm respirable particles

LEV suppliers often state “independently tested” and “up to 99.nn% efficiency”

THIS can be MISLEADING as filter Fractional Efficiency data is not readily provided.

LEV Systems are mechanical devices

- effectiveness reduces over time

- airflow indicators are ineffective for air quality

- process parameters determined at service vary

- respirable particles are not effectively retained

- pollution levels increase

- exposure increases the probability of ill health

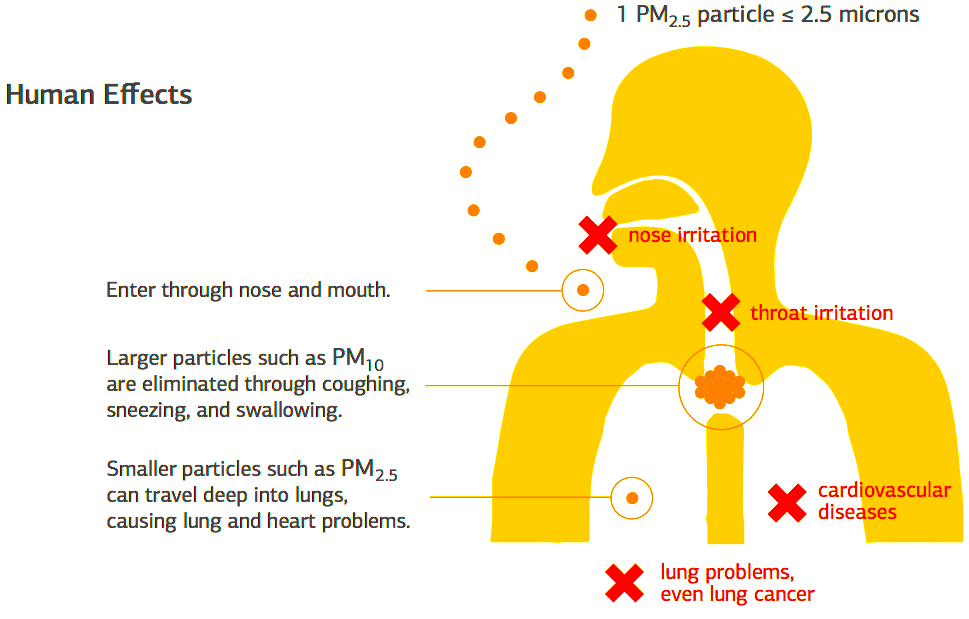

the risk to health - applies to dust, fumes & mist emissions

The air we breathe contains a vast range of particulates, from various sources. Inhalable particulates ,~>10µm (PM10), are generally irritants leading to itchy eyes, sore throat and runny nose. The bodies defences usually deals with these.

However, respirable particulates, ~<2.5µm (PM2.5), are invisible to the eye and when inhaled may enter the bloodstream and be transported around the body, lodging in the lungs, heart, brain, and other organs.

The fast majority of particulate sizes we see in Factories are PM2.5

The Health & Safety Executive report incidents of ILL HEALTH in the workplace each year.

Occupational Lung Disease leads to

- estimated 120,000 deaths each year

- 400,000 working days lost in Great Britain

- Exposure to Metalworking Fluid mist is always reported as one of the causes of Occupational Lung Disease

The Solution

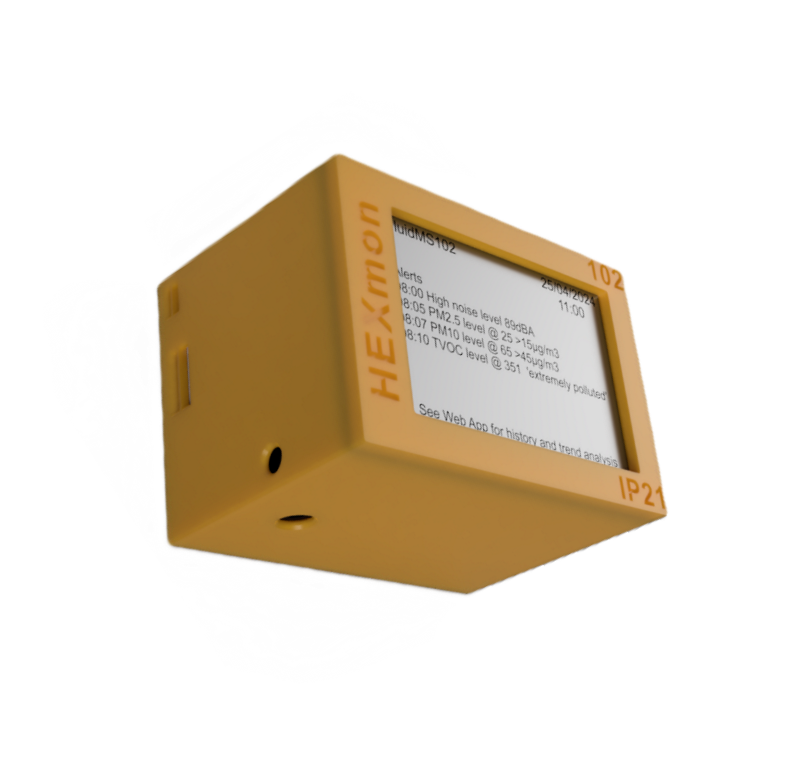

Visit the Solutions page to learn how HEXmon SENSOR provides better insight and assurance on the performance of control measures and exposure to daily trends in air pollution, noise levels and VOC's

HEXmon solves the problem of NOT KNOWING